sales@crd-devices.co.uk

Thirty-Four Years Plus G&P Technology Co Ltd Have been Manufacturing Quality Goods & Services

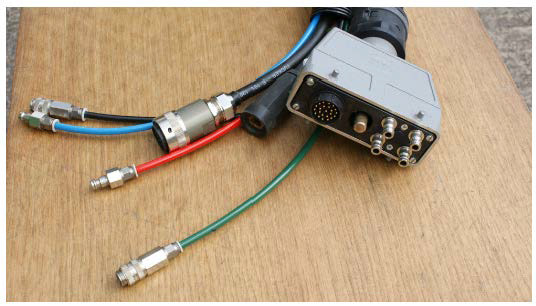

All of our assemblies are produced to ISO9001 :2015 standard by our very experienced and trained employees. Let us see your requirements - and go with our experience.

The testing we provide at G&P Technology includes Class 1 appliance testing as well as visual inspection. Class 1 involves two tests being undertaken on the appliance, these being an earth bond test and an insulation test. Visual inspections can be required when the customer wants to check that the equipment is in good working order. These will normally be done alongside a Class 1 test but that is up to the customer.

G&P Technology Co Ltd have a lathe and milling machine in house. We can do one off products or millions of parts for customers. We are always here to evaluate when machine work is required.